Recent Jobs

Job Spotlight

21180-QC Technician-Carlow Contractor

This is an 11-month contract. Shift cycle & premium – 2-cycle – 20% shift premium Purpose: This is a contract-based ...

Apply For This Job21116-QC Technician-Dublin Contractor

This is an 11-month contract, fully onsite. Responsibilities: • Receive and manage samples that come into the lab for stability, in-process ...

Apply For This Job21208-QC Analyst-Meath Contractor

This is a 7-month initial contract. It is a day shift role onsite. Purpose: In our start-up site, the role ...

Apply For This JobWhat Our Clients SayWe collect reviews from our clients so you can get an honest opinion of what working with us is really like!

Professional, prompt, and know what they are talking about. Highly recommend.

I found their professionalism and support invaluable. From the start they were constantly in touch with me regarding the process.

The Aphex team have a strong understanding of technical requirements and ensure clear and efficient communications throughout entire processes. Aphex has delivered on major point roles and on this basis I would highly recommend them for recruitment needs.

Being able to talk technical with Aphex really prepared me for the rigors of the interview process’.

Aphex demonstrates professionalism and show complete dedication to the needs of the recruiter.

Aphex provided excellent interview preparation and aftercare.

Recent Posts

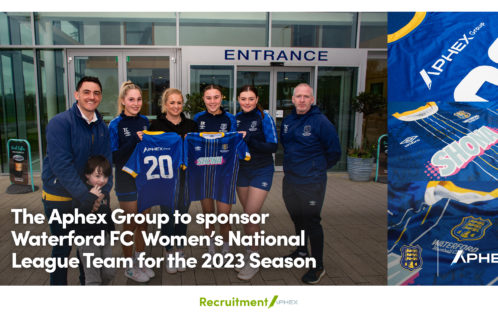

The Aphex Group to sponsor Waterford FC Women’s National League Team for the 2023 Season

We are thrilled to announce that we will sponsor the

Read More

Explore Life Sciences S.2 Ep.4: Eoin Gill, Director of Calmast, Waterford Institute of Technology

Eoin Gill is a director of Calmast STEM Engagement Centre

Read More

Explore Life Sciences S.2 Ep.3: Andy Crowley, General Manager Teva Pharmaceuticals Waterford

Andy Crowley is the general manager of TEVA- one of

Read MoreWhere our best finds the right fit for your organisation

Recruitment by Aphex is regarded as one of the leading in the South East. Our South East recruitment consultants repeatedly support and partner with businesses throughout Waterford, Dublin, Cork, Limerick, Meath, Tipperary and throughout Ireland.

We source highly skilled temporary, contact and permanent employees in science, human resources, finance, accounting, business, technology and administration to assist you in your recruitment goals. No matter what size your business is, we will provide you with the best in class result.

We have a customised approach to searching for top talent candidates along with our expansive and innovative database. This combination enables us to deliver the best candidates for roles.

Contact our Waterford recruitment agency to discuss your specific requirements.